Windows

Fresh air is what the Doctor ordered. In 1860 he may also have said, “Go west, young man.” In England, glass was not very common and did not get into homes other than nobles until into the 1600’s and 1700’s. That makes sense that it did not become popular in any country as making glass was an expertise trade and who was going to try and transport this fragile stuff across the U.S. in a covered wagon? Windows have been around for thousands of years but not operable, openable glass windows as we know them. A window opening was closed and covered at night or during inclement weather. Think of “Shutters” and suddenly you realize that a cute decorative item today was a functioning safety item a couple of hundred years ago. Even in the past 100+ years there have been design changes and then dual pane, triple pane, inert gas filled windows and the list of new fangled modern things is not going to stop. But there will always be some similarities and points to consider. So the various types comes into play depending upon the room, location, etc. This window section of this web site goes through a lot of material. Read what you want or need and save the rest for Trivial Pursuit with your friends.

Window Styles and Details

The photos above give some insight to windows you may encounter in a house and not be familiar with. Reviewing how many original designs came about, through history and the passage of time some of the details and information becomes forgotten or foggy to those not in the industry.

Let’s look at the “double hung” window as an example. From the 1800’s to modern current construction this window design is used. Why would this design be used? Casement windows were the first operable windows. In country homes, the animals would make noise if anyone came up to your farm and you were already awake at 5 am anyway. There were not many ways to keep a casement window “secured” for just a little fresh air. It swung wide open and you had to secure it open with the “shutter dogs”. Yes, that was the terms for the catch to keep the shutters or window open. As the industrialized countries built cities and than the Industrial Revolution created factories, think of the housing of England where rows of houses were squeezed together with several “flats” (apartments to us Yanks) would be in one slender, two or three-story structure. The double hung window did not swing out and the top window sash could be lowered allowing the hot air out of the interior. You could even put a nail or pin in the window to keep out Oliver Twist and other pick-pockets.

I have met many a buyer of a home and they were completely unaware that the top window in a double hung sash is designed to slide down to let out heat in summer. Hot air does not suddenly know how to dive 5 feet down from the ceiling to go out the bottom window. And for the last 50 years, unskilled labor paints the top window closed! Frozen solid is how you find most window tops. With a razor and a putty knife scoring the paint inside and outside, these windows can usually be made operational again. But it is a bit of labor.

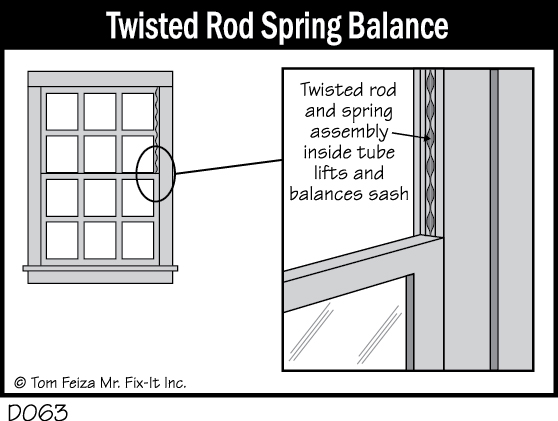

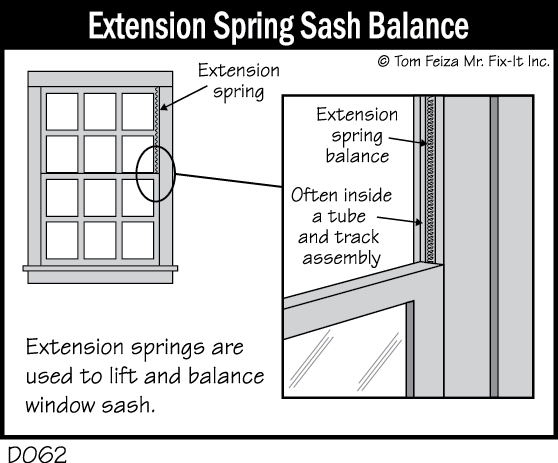

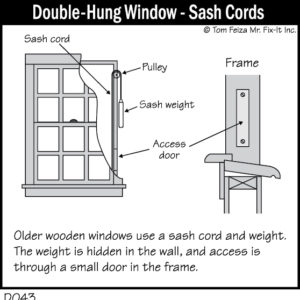

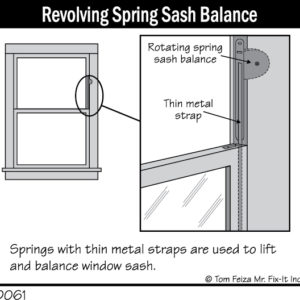

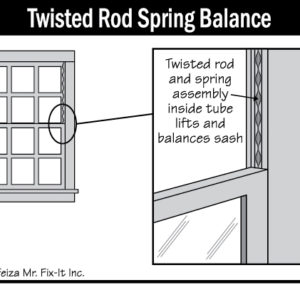

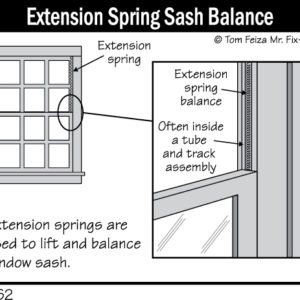

There are a few things that can go wrong with windows. One particular problem is what almost everyone has experienced. That is opening a window and it does not stay up. So you use the highly scientific and very complicated “book” or “piece of wood” to hold the window open for fresh air. This is what is known as a broken window sash. This can actually mean a failure of a similar part as windows changed over the years, but still is the part to keep the window open. Some of the first double hung windows had a pulley with a weight inside the wall framing attached to the moving frame of the window with a rope. The actual square moving frame of the window is the “window sash”. The rope was called the “sash cord”. It was connected to that wood square holding the glass. So far that sounds simple. The rope breaks and there is no counter weight to help balance the window to prevent it from falling.

Do not get confused now. When WWII ended, the pulleys and ropes were replaced in the early 1950’s with smaller coil springs and steel wires. We still called the part the sash cord. History marches on and the side hardware and springs began to look different with aluminum windows and then vinyl windows. You can still use the same term to describe what happens: “The sash cord broke.” See, easy to cover 150 years. Fixing it is another story.

Oldest windows. Take apart all the interior trim wood carefully exposing the pulley and weights. Find proper size rope and reconnect then replace or install new wood trim. $250 to $400 per window. It depends on who rips you off or is reasonable. Another option is to buy for less than $10 a spring clip and tap one into place on one side. This clip looks like a girl’s hair barrette. When pushed down the side of the wood frame, it pushes on the side wood creating tension and the window doesn’t fall. Do not put in two clips on the same up or same bottom window. You will lock that window in place and it will never open. Your choice of monetary expense.

For the aluminum windows and vinyl windows, call a window contractor. You don’t have the parts and the designs are similar but each no-name brand is just a little different. Save yourself a headache and call to see if the windows are under warranty.

And another part of a window that can and will fail is the glazing. Not the donuts, but the putty used in the 1800’s on was described as the window glazing putty. Past 200 years ago, if you had glass, you were rich and the glass wasn’t air-tight against wind anyway. With the advent of the putty, glass could be secured and it no longer rattled in the wind and cold air didn’t blow into the house off Lake Michigan in Chicago. And like everything in life, putty gets old. When it cracks and gets old it falls out of the windows. This really is a simple repair but appears to be a lost art in today’s modern world. Call a handyman and if he asks you, “What are glazing points?”, hang up and find another handyman. Glazing point are tiny little pieces of steel that first hold the glass steady and in position before you apply the putty.

New windows and new glazing! Basically all the aluminum windows have rubber “glazing”. It looks like a thin rubber strip or rope with a groove to hold the glass. The other side of this rubber rope has another groove that slips over the metal edge to hold it in place. You have probably already figured out that your newer rubber glazing has dried out and cracked from age. And you window rattles. And you want to try fixing it. Call a window company. To get the glass out and find the correct rubber strip for the aluminum frame, you have to take apart the two top and bottom pieces from the two side pieces. These all slip onto a corner bracket inside the channel that you do not see. You will most likely break it and blame the dog or child so do everyone a favor and call a window company. Along with newer windows also came newer codes for egress. What? Do you mean to get in and out of a window? Yes, a fancy word for climbing out of a window to escape a fire.

CodeWindow Problems

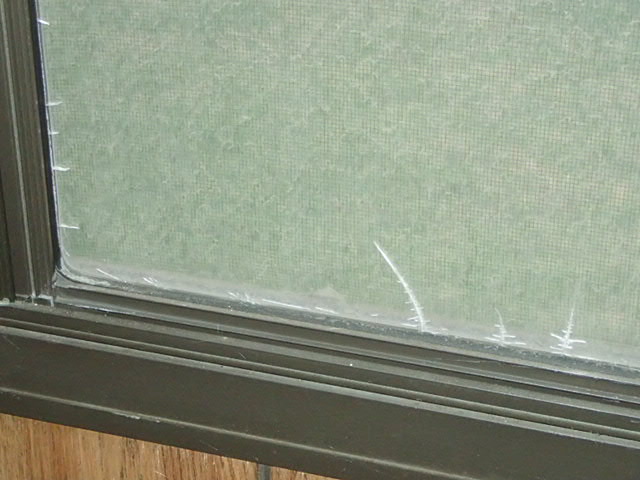

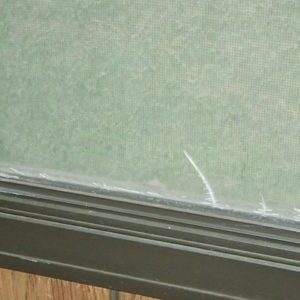

Vinyl windows have a similar flexing problem coming off the glass. Also when considering the quality in design, look to see if the vinyl window has an area to grab to “push” the window open instead of only pulling it open at the lock. Why? As the window flexes after thousands of cycles of opening and closing, the adhesive or silicone can come loose and separate from the glass. Continuing on with the quality of some vinyl windows, guess what gets hot in the sun? The internal seals on lower quality windows often has the adhesive release and come out of position. That doesn’t immediately mean the window will fog with an external seal failure, but it is one step closer. When a seal fails on a dual pane window moisture gets inside between the glass panes. That will lead to fogging and continues to get worse will actually have dripping water inside. This will not harm you but certainly can ruin a beautiful view out a window.

Other things that are common occurrences with vinyl windows is again incorrect installation. The window is an extruded part. that means that a big melted pot of plastic was forced into a mold and out comes a long channel or pipe if you will without holes. Remember that part about “no holes” to leak. similar to making PVC pipe, that machine will make 100 foot sections and they cut that into pieces sized for the window. During this fabricating a drain hole/notch is made to let the rain get out. Good thinking. But too many installers put a giant screw in the bottom channel that is not supposed to have any holes. This is supposed to be a water-tite frame and some guy puts a hole in it! It is correctable. If you have this situation consider this solution to prevent moisture blisters in the wall under a window, which I have seen. You can leave the screw or remove the screw. You are going to take your old toothbrush that is dry and dust the screw off and the immediate area so you can dab a bit of silicone over the screw head or remove the screw and fill the hole. Have a cup of water and wet you finger and smooth out the silicone so you do not leave a big bump so the window doesn’t close. Wipe your sticky finger on a paper towel and not on your pants or the carpet. do not worry about the screw removed because the window is held in by all the finish trim wood and can not longer move anyway.

All moving vinyl windows can come out of the track for cleaning. Pretty neat. If it is a single hung or double hung design, there are spring levers on the sides. Open window one or two inches so it is above the bottom channel. Squeeze both side levers on top of that moving frame in at the same time and you can lean the window out to have your helper clean. Or balance and clean with one hand. You’re an adult, you can figure that out. A double hung window can also slide down an inch or more and also swing in for cleaning. This should have a helper because you have two pieces of glass resting on your chest or stomache and slipping here is not a good thing. Do not twist the window sideways when you have it out to clean. It will fall out of the moving parts that go up and down in the side channels and the story will end with you breaking an expensive window. But when putting it back into the side channels, CAREFULLY push the sping-loaded clips in so the plastic clips do not break. Do not swing it closed like a car door and expect it to latch. Wrong. And when you think you have it in place, keep your hand on it and slide the entire window up and down in the track to be certain it won’t fall out if you missed getting it to click into place.

The sliding vinyl windows are just a little different. There may be little plastic spacers in the top channel that take up space. there is a picture of one incorrectly sitting in the bottom channel in the picture of a screw in the bottom track. When in the correct position, that spacer is to prevent burglars from lifting out the window from the outside. So position the spacer by simply sliding it in the top channel so when the window is unlocked and open fro fresh air, the window cannot be lifted up high enough to clear the channel and come out. Experiment with your special broomstick burglar restraint and these spacers. This way you can have fresh air and still stop some of the bad guys.

Vinyl Window Problems

Some more points to consider when installing windows is to avoid the developer tendency of thoughtlessly installing the cheapest and inappropriate window at certain locations. The first point is to look for a tempered glass label on any windows in stairways. Current safety guidelines require tempered glass at stairwells because people trip and fall or throw the box they are holding when falling. Look for the tempered glass label. You may never have an accident, but it only takes one to be a very bad memory of the trip to the emergency room.

Installing “retro-fit” windows can wonderfully upgrade a home. With dual pane windows you do make the house quieter and more energy efficient. The biggest problem seems to be finding a contractor to do good work for a reasonable price or do you go with the one who offers you $10,000 off if you call within the next 15 minutes on a TV or radio commercial. Well how much was that guy charging in the first place? Cost vs. problems. This is where referrals are wonderful things. Ask your friends at work or church, etc. Some of these web things are constantly coming up with consumer protection agencies stating that a large percentage of positive ratings came from the same IP address, meaning that the contractor put up his own favorable ratings 100 times under different names. But this site isn’t to recommend a contractor. But we can certainly show you the level of craftmanship and quality to look for when you ask to see Aunt Mary’ new windows.

It can be a 50/50 shot. The Contractor-installer is half of the formula and what window brand/manufacturer did he install is the other half of the formula? If one half of the formula is poor, the other half doesn’t matter, some parts of the installation could still fail. Let’s start with the craftsmanship. Many original window installations have the exterior window sill sloped down to shed rain water. Almost every retrofit window has a flat, level bottom of the frame. That means there could be a gap at the bottom of the window on the outside edge.

If you are not going to re-stucco the house, leaving the original window frame in position is often the method preferred as the original window frame did not leak. Why break things open and damage the stucco? So if there is a gap on the bottom of the frame what should be done. Some people will take a “Sawzall” and planer and trim/adjust the original oak sill to almost level after measuring so the new window just slips into place. This is then secured and caulked and Voila! No damage to old interior frame or exterior frame or stucco. But that only works if a special ordered size, custom fit window is ordered.

Rats. Most guys simply buy what the store has in stock and older houses often had add dimensions. Today’s economies of scale mean they make a million of this size to keep the price down. And that means if you want custom sizes….. for a really good fit, you have to wait a few weeks. Well if you are an impulse buyer, forget it. Custom work requires patience. It is not like a microwave or Pop Tarts for breakfast in 60 seconds. All that blah, blah to show what some of the quick solutions to installing windows will look like if not done well.

Vinyl windows have a wide range of quality. Even within a single company’s model lines. First there is the air spacing between the dual panes of glass. 1/4, 1/2 or 3/4 inches or those approximations. The wider the window, the greater the thermal barrier between heat and cold. That equates to energy efficiency and the wider/thicker window provides better insulation and noise suppression. Than you also have the actual thickness of the glass. A small fractional difference (or millimeter) will also improve the energy efficiency, noise suppression and strength. Than you can add coatings to reflect the sunlight, add argon glass between the glass. Getting this into perspective gives you choices just like buying a car: Old VW Beetle or new Cadillac. And sometimes you do get what you pay for.

Window Installation Problems

Kitchen Windows. A cool breeze at the kitchen sink can be welcome during warm days or preparing the feast for the family and friends. Consider your kitchen floor plan. Whenever there is a window behind the sink, can you reach it to operate/open it? There can be some corner sinks with a double hung window or maybe a sliding window. If you are 5′ 2″, can you even reach over the sink to open it? Without tweaking your back? That could be a location better served with a casement window with the bottom crank handle closest to the walkway (not in the far corner). Garden windows let in a lot of light and most designs have two small single hung panels on the sides. If you can reach them it is better but simply plan ahead before installing something that is difficult to reach. Convenient operation is a pleasant way to live instead of going to the garage for a ladder each time.

Kitchen Windows

Bathroom windows. This area is almost always the easiest to improve if you are going to replace a window. Why do I say that?

A. Let’s start by putting in an obscure window. That is one that has glass that is not crystal clear. It can be called frosted, rain-glass and plenty of other designs but they all mean that people cannot look in at the woman of the house taking a shower. And the glass still let’s in some light.

B. I do not know why anyone would put in a “single hung” or a “sliding” window in a bathroom. If they installed any obscure glass, you have to open the window to get the steam out and not create mildew all the time, the woman’s modesty is compromised! A single hung window opens “UP” at the bottom and everyone can view Lady Godiva. In addition the steam in the bathroom will not dive down 5 feet from the ceiling to get out the window as hot air rises. So the same with a sliding window that is obscure. You open it up and everyone can look in. A better solution is to install an obscure “double hung” window. Modesty is maintained. During the shower, you open the “top” window going down that is close to the ceiling at 6’8″ and steam goes out and a women’s modesty is maintained. You can also opt for an awning window higher on the wall that does not allow any peep show. Yes, and awning window ins’t that bad and a hopper window is very good also.

C. If you are going to replace a bathroom window, is it in the shower enclosure? Many old bathtub/shower combinations had a very low window in the enclosure. This will always rot the wall. Water will get into the wood frame or past the tile or something, but it is doomed. If you can, break the stucco and install a window higher in the wall.

Another bathroom note is that any window next to a bathtub or inside a shower enclosure has to be made with tempered glass. Slipping in soapy water may have the occupant swing arms and hands or go head first into glass. Pay attention to the close proximity of glass to the wet enclosure areas in the bathroom to minimize accidents. And it may sound strange, but the glass blocks often used for part of a wall or to allow light into a bathroom are not considered as windows. That means they are not required to be tempered glass. That may sound a little scary, but true. They may be heavier walled items that a thin piece of glass, but that is the current rules.