Electrical Wiring

There are wires that course through the walls and ceiling of every structure. Depending upon the design, wiring can also be under your feet in some cases. No matter what age house you have, the wiring has to be protected against accidents. The surprising part about electrical codes is that there always seems to be somebody who tries something that turns out to be dangerous and burns down the house. Every year you will read about a Christmas tree burning down a house. Now how can that happen? I have never burned down a house yet. But were two boys playing tag around the tree and tripped on a cord? Did a dog chew the wire that got hot and ignited wrapped presents? There are numerous ways that an accident can happen that we would not readily think up. But leave it to billions of people living on earth and the one guy they called to help, “Uncle Wilbur” who figured out how to burn the place down.

There are actually many areas concerning electrical wiring and this area is going to cover a whole lot of material and lots of examples. Just the same, when in doubt, hire an electrician and not the painter who painted all your windows shut.

One item that is sometimes overlooked when remodeling and adding electrical wires is to install “nail plates” to protect the wiring from drywall screws. If 2 x 4 studs are used, a drywall screw may be able to penetrate the wood and pierce the insulation and so a nail plate is supposed to be applied to protect the wires. If a 2 x 6 stud is used, drilling the pass-through hole in the “middle” of the stud for the cable, the wire would be far enough inside to generally be safe from drywall screws. Check your local building codes and pay attention to what is going into the house as they are remodeling.

Wiring Construction

Wiring is supposed to be secured to the electrical boxes. Steel boxes use clamps and most plastic boxes have friction tangs to hold the wire. Why? because if someone accidentally pulls on a wire, it could pull apart the spliced wires. If there is an electrical load at the time, that will “spark” when that happens that can start a fire. That separated wire now has one “hot” side that could touch metal and turn the faucet on or the window or any metal in contact. Very scary. Clamps are cheap so use them.

The nonmetallic sheathed wiring commonly known as “Romex” is also supposed to be secured outside of any electrical box within 6 inches. The wiring is supposed to be secured the floor joists and secured or protected within 6 feet of access to the attic. Most of these conditions may not be seen unless it is new construction. The completed house has all the drywall installed and the wiring is covered. These conditions will naturally be a mystery when you walk through the house. Do not lose sleep over this and only freak accidents or someone using a 3 inch screw may cause trouble in the future.

Knob and Tube Wiring

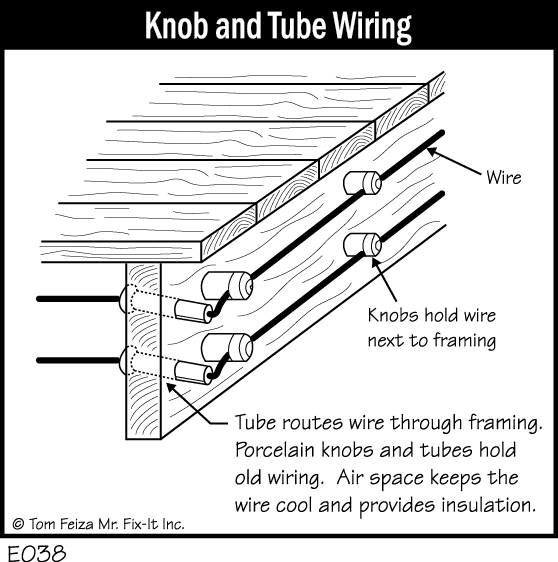

There is an older wiring type found in houses constructed prior to WWll. Knob and tube wiring was titled by the ceramic “knobs” and ceramic “tubes” that were used to support the wires and also thread the wires through the framing. This older wire only had a cloth wrapping that did not insulate very well. Different than after the War when the introduction of a plastic coating for insulation was covering the copper electrode. Much of this “newer” wire around 1945 also had a cloth wrap for extra protection and was used up into the early 1960’s in some areas, it was visually confusing to the non-educated people that had already been shocked once in their life and swore they would never touch another wire.

Back to the knob and tube. We all know you can shuffle your shoes on the carpet and send a static electricity spark into your brother’s arm. Cloth does not stop electricity. Your brother’s shirt did not protect his arm. That was the dangerous thing about the original electrical wiring. When Thomas Edison introduced wiring to carry electricity, they immediately figured out that you do not touch two wires at once! And you do not forget that after you get shocked. To prevent the electricity from jumping across the two wires, the positive and negative wires (hot and neutral as we say) were always at least 6 inches apart. And to prevent any overheating in the wires from burning the wood, ceramic knobs were used to support wires and ceramic tubes protected the wood when wires were threaded through the wood. So the “Knob and Tube” nomenclature stuck and some technicians might say “K & T”, but that was the first type of wiring in housing.

Knob and tube

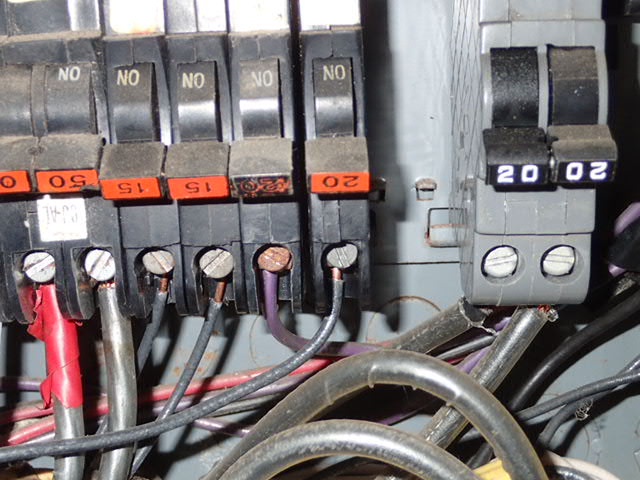

Aluminum Wiring

There was an era in the end of the 1960’s where the introduction of aluminum wiring was used. Some reasons for this new product was the need for copper during the Viet Nam War. The first generation of aluminum wiring had some problems. Most of the concerns were found in houses built or remodeled between 1965 and 1972.

A short aside, the previous generation of wiring sometimes had metal conductor leads that were “tinned”. When connecting wires, solder was applied onto the ends for a non-corroding tip. Most people are aware that copper “oxidizes” and turns green then brown when exposed to oxygen for a while. This oxidation impedes the electrons from moving from one corroded wire to the next. Tinning the wire with solder prevented the green oxidation from developing and improved the life-span of the electrical work installed. Scratching the solder showed a copper conductor is still underneath and this is simply history, not life or death issues effecting the connectors anyway. So let’s get back to the real aluminum wires.

Two issues came up with aluminum wiring after the first few years. Aluminum still conducts electricity and the trade off for non-mission critical systems like a simple light bulb appeared to work fine in the beginning. Heck, pulling softer aluminum wires through turns in conduit and buildings was also easier. This made no difference to the electricians and there was plenty of natural raw material available. Slowly things began to occur with aluminum wiring.

The first formula had latent issues that came up. The first generation of aluminum wiring could only be bent a few times back and forth and then it would snap/break. It was determined that the first aluminum alloy formula had too much iron and was more susceptible to oxidation. Most all metals “oxidize” in some fashion except gold. You have noticed that older aluminum screen doors and the tracks turn white. That is the corrosion that can effect the electrical connections.

Now when installing the aluminum wiring in the homes from 1965 on, you would usually put it in and leave it alone. But if any changes were made to an outlet or light fixture, a wire could snap. On top of that, it became apparent that screws were coming loose! Now who would loosen up screws? Nobody did. The thermal expansion rates of aluminum and steel are wide apart. That translates to the aluminum wire getting hot and expanding on a microscopic scale. This put pressure on the screw holding the wire. As the aluminum cooled, it became smaller, hence after a number of cycles of use, the steel bus bar holding the wire and the screw appeared to back off the wire. Not much different than the screws getting loose on a door hinge or knob after a thousand times. So what is the big deal?

Well, loose wires that are not properly secured have less contact between the metals but the same amount of electricity tries to cross over the wire contact point. The smaller the point, the hotter it gets and the screws become more loose. Soon there may be a small gap and that makes micro lightning bolts like the Dr. Frankenstein Tesla Coil. That micro spark gets bigger, hotter and guess how a fire starts in a wall? Loose wiring of any type can start a wire, but the aluminum happened with frequency.

What added to this was that the previous method for connecting a wire to any fixture or circuit was to strip the insulation off leaving a bare conductor. That wire was twisted into a half loop and held by a screw. This is where screws could come loose on outlets, lights and breakers use the method of securing was designed for copper in the old days. So thankfully engineers working on the second generation of aluminum wiring had also develop some changes in securing to fixtures.

Understanding the use of alloys after building planes for decades, other mixtures/alloys were tested finally designing a compound that could withstand more bending without snapping. Great! Secondly, the old screw method was improved with a clamp at the breaker or fixture/outlet. The screw would not heat up in the same manner and the clamping steel or copper was a buffer in the thermal expansion and contraction of the aluminum. This allowed the wires to stay secured for years. Current electrical products will have a small designation that it is approved for copper and aluminum wiring and the element abbreviations of “CU/AL” will be visible.

Retrofitting circuit wiring in a house with aluminum can often be with a short pigtail and is often called a CopAlum connector. Get it? That stands for copper and aluminum. Now readily available and designated as an approved repair by the CPSC (Consumer Product Safety Commision). This is a short set of wires and a special connector so the aluminum connection cannot come loose and the new copper lead easily is secured.

That was a lot of information most of you wanted to skip. Now back to what can go wrong with wiring. It is really pretty easy and it makes sense as soon as you read it.

All wire splices are supposed to be inside an electrical box. You would almost never see an electrical box unless you peek in the attic, crawlspace or have an unfinished garage. So why the rule? Because wire splices can be pulled apart and start a fire. You read that up on top of this page. Well let’s add to that and remind you that all wires are to be terminated inside a box. Even if it is future wiring for the patio lights next week or next year, it had better be in a box. What if the breaker or switch gets flipped and there are live wires present. Scary thought. I have found that too many times. Someone forgot to finish the job and it is dangerous. Along with that the boxes are supposed to be secured to the framing. Loose boxes can allow movement and if not twisted together properly, the splice can come apart inside the box.

Splices in Boxes

Attic wiring. The biggest issue is not protected within 6 feet of the opening. That sounds like a funny rule, doesn’t it? But wait a minute. How many homes after Christmas will find Dad on a 6 foot step ladder (not 8 foot) putting ornaments and Christmas lights up through a small hole in the ceiling? And when he finagles that box through the tiny hole, he can’t see anything but pushes it aside and then another box and another. As he pushes those boxes farther from the opening, they slide along and snag some wires in the dark. “Fizzzz-Pop” goes the electric wiring when pulled apart, making a large spark on a cardboard box. You might get to be on the television news that night for the fire department went to your house. That is why there are rules.

Wiring Attic and Crawlspace

Wires and conduit also have to be secured to floor joist or in the basement for similar reasons. If on the soil, there will be enough moisture in the dirt to corrode things over time and cause trouble. Poor connections or sharp edges on the conduit can damage things. The worst is crawling over wires and getting snagged on your shoe or belt. When the wires pull apart, you may never come out. Enough said on that.

Extension cords are designed to be temporary uses, not permanent wiring. “But everybody does it!” is not a very good excuse.

Extension cords

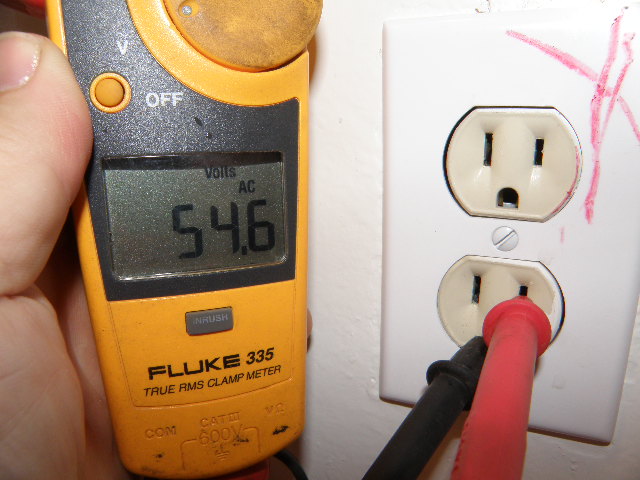

Some wiring issues are from incorrect connections. Voltage on the ground will make the high frequency computer or modern TV act very funny or blow internal appliance circuits. A fearful situation is when someone brings a powerful 240 volt line into the garage. From that box one guy takes one wire to make a 120 volt outlet right next to the 240 volt box for his compressor. The next family that moves in, the guy wants another 120 volt outlet for a vacuum or power tool etc. He knows he needs two wires on the outlet but connects not a 120 wire and than a neutral wire, but he grabs two 120 wires (remember this box has 240 volts that is 120 + 120) and connects them to a household outlet. As soon as he tries to vacuum the car or plug in a radio it will blow up from 240 volts. Scary. Hire an electrician.

Along with that, there are the creative people who attempt to be electricians. I have to admit, that we were on Gilligan’s Island we would be happy that it worked for a day or so. But in all reality, the risk is too high when fires or electrocution are possible.

Electrical wiring Misc.

Another “wiring” oversight is when you finally decide to pay a plumber to get rid of the old galvanized steel pipe and put in copper pipe. Great. When this work is done there could be something that was forgotten. A. If there was a GEC (Grounding Electrode Conductor – okay ground wire) on the steel pipe…….that is now cut off, the main panel is not properly grounded if they did not put it back on to the new copper. On top of that, the old steel clamp cannot go on the copper because it will cause corrosion. So you need a new brass clamp. Under $10 but needs to get done.